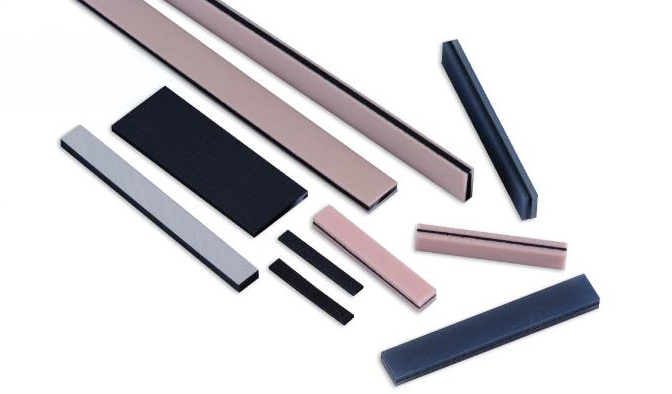

產品描述

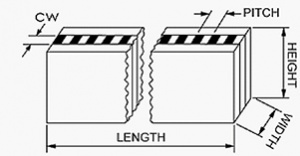

導電條設計原理是將導電矽橡膠和絕緣矽橡膠層層相疊再熱壓成型,利用一個與數個導電體接觸液晶顯示模組與電路板的電極表面,產生導電的效果;導電條可分為全導電與半導電二種材質,一般常用的規格型式如下:

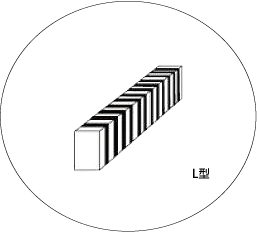

『L』型式為全導電材質。

用途:用於數位相機、電子鐘錶、電子計算機、體溫計…等液晶顯示模組。

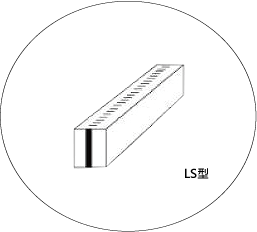

『LS』型式是以全導電的材質為中間基礎,另外在兩側覆加絕緣矽橡膠。

用途:用於手機、電子秤、測試儀器、PSP…等液晶顯示模組。

『LG』型式是以全導電的材質為中間基礎,另外在兩側覆加發泡絕緣矽橡膠。

用途:用於筆記型電腦、工業儀表、音響面板、汽車儀表板…等液晶顯示模組。

- Technical Information

- L Type Tolerance List

- 使用手機或解析度較少的行動裝置瀏覽本頁面時,下方物性表可左右滑動觀看。

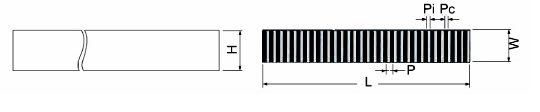

| Item | Unit | 0.05P | 0.10P | 0.18P | 0.25P | |

| Pitch | P | mm | 0.05 ± 0.03 | 0.1 ± 0.04 | 0.18 ± 0.05 | 0.25 ± 0.05 |

| Length | L | mm | 1.0~5.0 ± 0.1、5.1~30.0 ± 0.2、30.1~70.0 ± 0.3 | |||

| mm | 70.1 ~ 120.0 ± 0.4、120.1 ~ 200.0 ± 0.6、200.1 ~ 300.0 ± 0.8 | |||||

| Height | H | mm | 0.8 ~ 5.0 ± 0.1、5.1 ~ 25.0 ± 0.15 | |||

| Width | W | mm | 0.4 ~ 8.0 ± 0.1 | |||

| Properties | 0.05P | 0.10P | 0.18P | 0.25P | Unit | Test Method | |

| Physical | Compression Set | 15~20 | 15~20 | 15~20 | 15~20 | % | — |

| Operating Temperature | -25~+85 | -25~+85 | -25~+85 | -25~+85 | ℃ | — | |

| Mechanical | Specific Gravity | 1.15 | 1.25 | 1.25 | 1.25 | g/cm³ | ASTM D792 |

| Tensile Strength | 50~60 | 50~60 | 50~60 | 50~60 | kg/ cm² | ASTM D412 | |

| Elongation | 250~330 | 150~200 | 150~200 | 150~200 | % | ASTM D412 | |

| Hardness | 65±5 | 65±5 | 65±5 | 65±5 | ShoreA | ASTM D2240 | |

Electrical |

Voltage Breakdown | 23~27 | 23~27 | 23~27 | 23~27 | Kv/mm | ASTM D149 |

| Volume Resistance | 0.7~1.0 | 4~6 | 4~6 | 4~6 | Ω˙cm | ASTM D257 | |

| Insulation Resistance (500VDC) | 1 x 103 | 1 x 103 | 1 x 103 | 1 x 103 | Ω | ASTM D149 | |

| Regulatory | RoHS Compliant |

Yes | Yes | Yes | Yes | — | Lab. Certification |

-

The above testing results comes from laboratory report, information are for your reference only .

- Technical Information

- LS and LG Type Tolerance List

- 使用手機或解析度較少的行動裝置瀏覽本頁面時,下方物性表可左右滑動觀看。

| Item | Unit | 0.05P | 0.10P | 0.18P | 0.25P | |

| Pitch | P | mm | 0.05 ± 0.03 | 0.1 ± 0.04 | 0.18 ± 0.05 | 0.25 ± 0.05 |

| Length | L | mm | 2.0~20.0 ± 0.15、20.1~90.0 ± 0.35、90.1~150.0 ± 0.6 | |||

| mm | 150.1 ~ 200.0 ± 0.8、200.1 ~ 270.0 ± 1.0、270.1 ~ 300.0 ± 1.5 | |||||

| Height | H | mm | 1.0 ~ 5.0 ± 0.1、5.1 ~ 20.0 ± 0.15 | |||

| Total Width | W | mm | 1.0 ~ 2.3 ± 0.1、2.4 ~ 5.0 ± 0.15 | |||

| Conductor Width | CW | mm | 0.4 ± 0.05 | |||

| Properties | Component | LS Type | LG Type | Unit | Test Method | |

| Physical | Compression Set | — | 12~18 | 12~18 | % | — |

| Operating Temperature | — | -25~+85 | -25~+85 | ℃ | — | |

| Mechanical | Specific Gravity | Insulator | 1.15 | 1.15 | g/cm³ | ASTM D792 |

| Conductor | 1.25 | 1.25 | ||||

| Edge Insulation | 1.1 | 0.6 | ||||

| Hardness | Insulator | 65~73 | 65~73 | ShoreA | ISO7619 (Type A) | |

| Conductor | 63~67 | 63~67 | ||||

| Edge Insulation | 20~30 | 17~23 | ||||

| Electrical |

Voltage Breakdown |

Insulator | 23~27 | 23~27 | Kv/mm |

ASTM D149 |

| Edge Insulation | 23~27 | 2.0~2.5 | ||||

| Volume Resistivity | Insulator | 1 x 1014 | 1 x 1014 | Ω˙cm | ASTM D257 | |

| Conductor | 3~6 | 3~6 | ||||

| Edge Insulation | 8 x 1013 | 1 x 1011 | ||||

| Insulation Resistance (500VDC) | — | ≤1 x 103 | ≤1 x 103 | M.Ω | ASTM D149 | |

| Regulatory | RoHS Compliant |

— | Yes | Yes | — | Lab. Certification |

-

The above testing results comes from laboratory report, information are for your reference only .